Industrial meat grinders / mincers

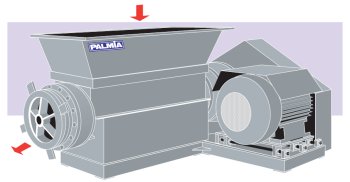

The PALMIA® industrial meat grinders are top-quality, precision made grinders which can grind both fresh and deep-frozen raw material.

The PALMIA® industrial meat grinders are top-quality, precision made grinders which can grind both fresh and deep-frozen raw material.

Products that are commonly ground in the meat industry are, for example, pig meat, beef, sheep meat, animal fats, fish, animal bones and grinding of carcasses left over from slaughter as feed material.

PALMIA grinders are safe and efficient

Our grinders meet the latest food safety and industry device requirements and standards. We have paid particular attention to operational safety and efficiency.

The construction of the grinders has strong focus on hygiene. The use and maintenance of grinders is made as safe and easy as possible.

General

The PALMIA® grinders are manufactured either of stainless steel or normal steel painted. The operating machinery is fully protected.

The diameter of the feed spirals varies from 160 to 400 mm. The lengt of the knife housing / feed spiral can be selected according to the properties of the raw material to be ground. The grinders are used for the grinding of fresh and deep-frozen raw material, such as meat, fat, fish, bones, offal etc. The motor outputs are from 7,5 up to 90 kW, and the capacity up to 30 tn / h.

Suitable industrial meat grinder for your needs

For meat processing, the PALMIA grinder 160-series uses fresh meat.

The 200-series grinders can grind fresh and frozen pre-crushed meat.

The 250- and 300-series grinders can grind fresh products and small blocks of frozen meat.

The 400-series grinders grind fresh products and normal blocks of frozen meat.

Palmia grinder 410 has been developed and designed specifically for grinding bones. The coarse grinder or Palmia grinder 255 has its own rotational speed of adjustable blades and this grinder model is very well suited for grinding meat products used in meat assortment prior to adjustment and salting.

Also, minced meat for pre-cut raw material, because the different operating mode of the device cuts the product without crushing or greasing.

There are two different sizes of PALMIA crushers available. The crushers are made for pre-cut of whole carcasses and various types of bones. It is easier to process further the pre-crushed products by their intended use and they are well suited for pneumatic transfer, for example.

Why choose PALMIA grinders

The food industry is frequently faced with new challences when stricter standards are carried out and manufacturers need to discover more competitive and ecological ways to produce food.

In results of Palmiatek’s decades-long key solutions and new technology development, we can be proud of the high quality, safety, ease-of-use and long service life of our PALMIA devices.

Using PALMIA devices, you can process your product technologically correctly, quickly and economically. All PALMIA devices are manufactured, assembled and tested in our factory. The quality of the device is controlled from the raw material to the final product. Our continuous product development ensures that any PALMIA device is of the highest quality now and in the future. We want to make sure that your device also meets your high demands.

Any spare part and consumable for the PALMIA devices is manufactured according to the same strict quality requirements as the devices.

Coarce Mincer

The coarse mincer (series 255) has been desingned for the grinding, prior to standardizing and salting, of the meat assortments used in meat products, as well as for the pregrinding of minced meat raw material. The machine´s unique way of operating cuts the product without crushing material.

Crushers

The PALMIA® crushers have been manufactured for the pregrinding of whole carcasses and various types of bones. Precrushed materials are well suited for example for compressed air transfer.

Crusher PBK60_PBK100 Grinder 410

PDF-brochures

Grinder 160 Grinder 211 Grinder 259 Grinder 312 Grinder 412 Grinder 258 Grinder 308 Grinder 408